KEOL offers within its KEOLab manufacture, a study laboratory,tests and trials on the behavior of materials in order to provide the most suitable solutions and answers to your problems.

The studies and tests that we make available to you will allow you to verify the feasibility of your project, to secure the choice of adhesives and selected materials, and to define a process that meets your constraints.

The studies make it possible to choose an adhesive taking into account the materials to be assembled, the living environment of the assembly, the stress modes and the mechanical strength requirements.

The tests carried out in the laboratory make it possible to measure the surface energies of the substrates (polar and dispersive), the mechanical strengths in tension, shear and compression, as well as the aging of the assemblies in a climatic chamber.

20 à 5000 KN

Réalisation d’éprouvettes collées pour mesurer la résistance

Mesure des énergies de surface et définition de l’enveloppe de mouillabilité

Vieillissement accéléré en humidité/température

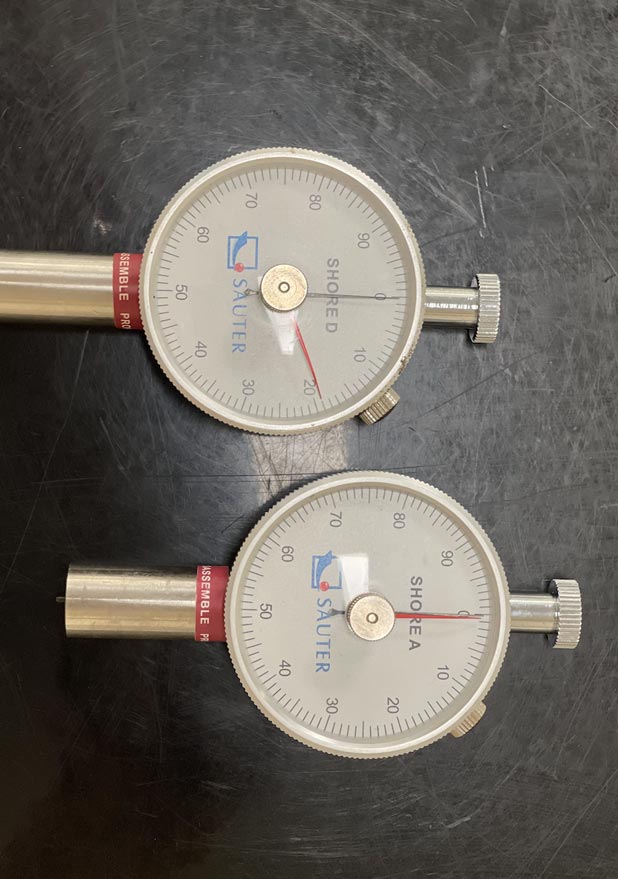

Mesure de la dureté des colles et résines Shore A et Shore D