The adhesives and coating products are an alternative to traditional methods of assembly and protection. Technical bonding / coating fixes the materials together but also lightens the structures, protects against corrosion, dampens shocks and vibrations, reinforces the aesthetics of the assembly, etc.

During assembly, the sealant spreads between the faces of the gasket, filling gaps, voids, scratches and surface irregularities. After assembly, the gasket polymerizes and provides a lasting seal.

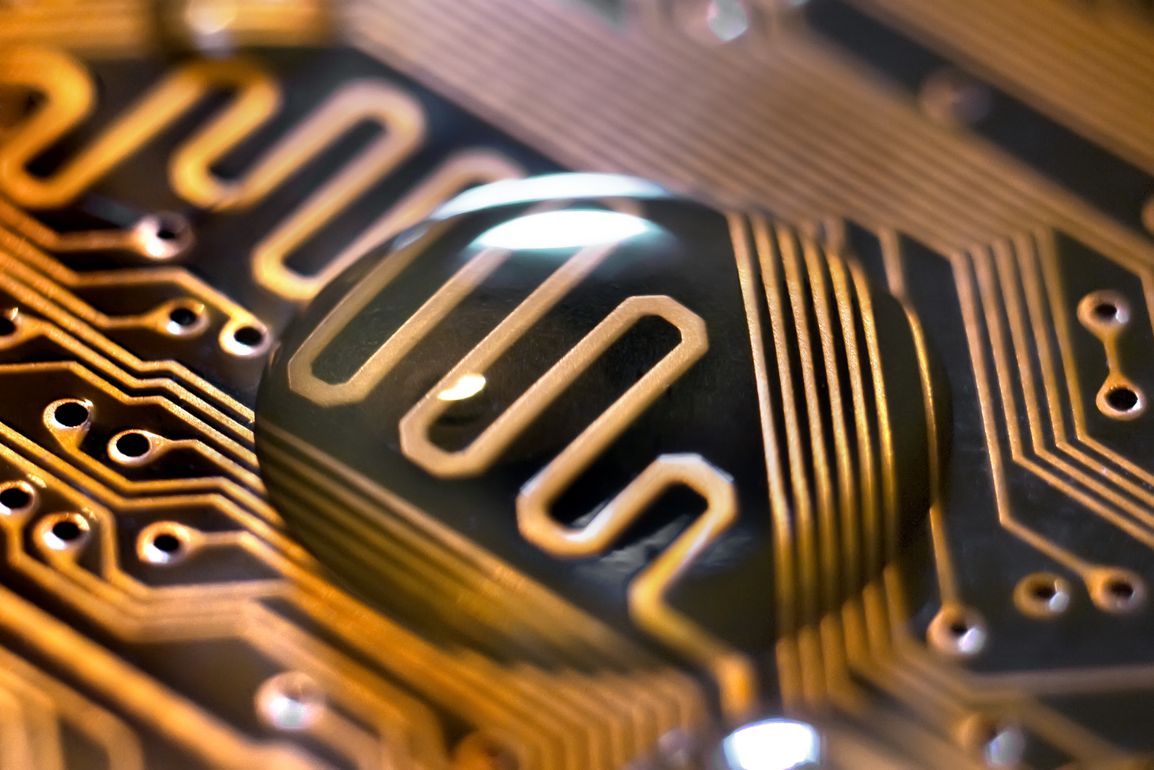

Bonding and sealing of parts for the automotive, medical, railway, aeronautical and high-tech industries.

Sealing bonding service carried out using RoHS and REACH approved adhesives in single and two-component bases (epoxy, PU, UV, silicones).

The transparency of an assembly is one of the most important criteria, particularly in the cosmetics sector where aesthetics is essential but also in other sectors such as the automobile, electronics and medical. The discretion due to the transparency of the adhesive points brings the visual purity of the assembly for a high quality aesthetic of the products.

Good mechanical strength of a bonded assembly is essential in the context of resistance to breakage or deformation under the action of physical (pressure, temperature, tension, bending, etc.), chemical (corrosion, etc.) or other forces or phenomena.

Impact resistance (or toughness) is the ability of a material to resist cracking due to the shock wave passing through it. Tested on concrete or impact, impact resistant bonded assemblies contain low hardness adhesives and have high elongation at break.

During assembly, the sealant spreads between the faces of the gasket, filling gaps, voids, scratches and surface irregularities. After assembly, the gasket polymerizes and provides a lasting seal.

Bonding and sealing of parts for the automotive, medical, railway, aeronautical and high-tech industries.

Sealing bonding service carried out using RoHS and REACH approved adhesives in single and two-component bases (epoxy, PU, UV, silicones).

The transparency of an assembly is one of the most important criteria, particularly in the cosmetics sector where aesthetics is essential but also in other sectors such as the automobile, electronics and medical. The discretion due to the transparency of the adhesive points brings the visual purity of the assembly for a high quality aesthetic of the products.

Good mechanical strength of a bonded assembly is essential in the context of resistance to breakage or deformation under the action of physical (pressure, temperature, tension, bending, etc.), chemical (corrosion, etc.) or other forces or phenomena.

Impact resistance (or toughness) is the ability of a material to resist cracking due to the shock wave passing through it. Tested on concrete or impact, impact resistant bonded assemblies contain low hardness adhesives and have high elongation at break.